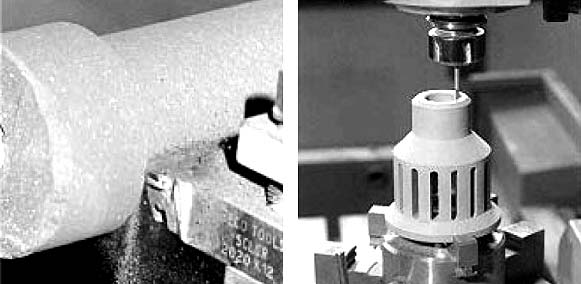

Presenting modern advances in the machining of ceramics and composites this work offers broadly based fundamental information for selecting the appropriate machining processes and parameters developing successful manufacturing strategies and designing novel machining systems.

Machining of ceramics and composites.

In a way machining composites actually turns the machining process upside down because the burden of the shop s attention shifts to different parts of the process.

It focuses on scientific and engineering developments affecting the present and future of machining processes.

Machining of ceramics and composites manufacturing engineering and materials processing.

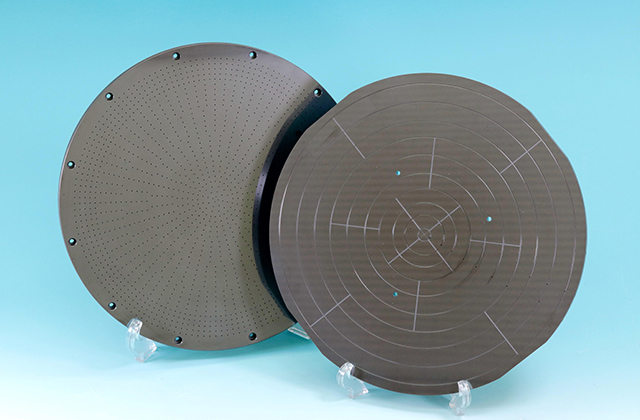

Machined ceramics is a precision ceramic machining company with many unique capabilities.

Free shipping on qualifying offers.

In this paper the effects of whisker orientation on the material removal rates and mechanisms in ultrasonic machining of al2o3 sicw ceramic composites are reported.

Continuous fiber reinforced sic ceramic matrix composites frcmcs sic are currently the preferred material for hot section components safety critical components and braking components in the aerospace energy transportation with high value and have triggered the demand for machining.

It was found that the material.

Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

Carbon fiber machining creates carbon dust which is both harmful to lungs and also can damage electronics because carbon conducts and the dust will.

Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material.

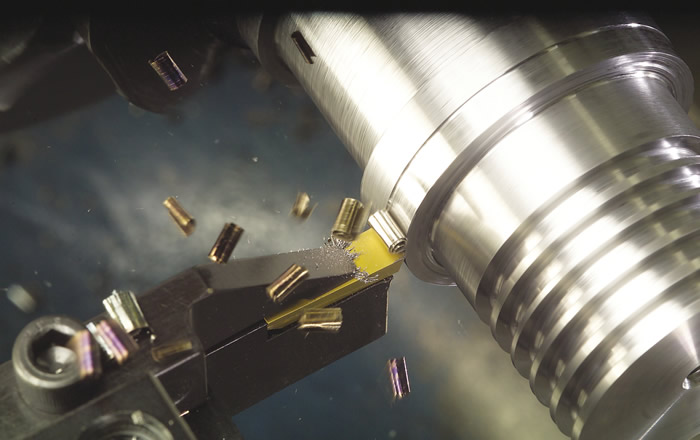

Typical machining create a reasonable amount of mess from chips but machining composites in general creates a huge amount of dust and mess from only one session of machining a typical composite.

Presenting modern advances in the machining of ceramics and composites this work offers broadly based fundamental information for selecting the appropriate machining processes and parameters developing successful manufacturing strategies and designing novel machining systems.

Surface quality of the electric discharge ground ceramic was better with no formation of surface sub surface cracks pits or micro pores.

Edm of al 2 o 3 based ceramic composites.